The 7 best professional 3D printers in 2024

What is the best professional desktop 3D printer?

There are so many different 3D printers on the market today that it can be a real challenge to choose one. When every penny of your quarterly budget counts, you want to make sure your professional 3D printer is adapted to your needs. Material compatibility, build size, ease of use, workflow, software, and many more elements come into play.

To help you cut through the clutter, we made a shortlist of some of the best professional 3D printers available this year. These benchtop and desktop FFF (fused filament fabrication) 3D printers for professionals offer a great combination of features, performance, and reliability, and come from well-established brands. They are ideal tools for rapid prototyping and iterative design processes, and are also suitable for low-volume production series. Keep in mind, though, that while part quality does depend on your printer’s performance, it also greatly relies on your choice of materials.

Towards the end of this article, we also provide a brief buying guide where you can learn more about different 3D printer specifications such as printing temperatures, layer thickness, dual extrusion, and more.

Best benchtop 3D printers for professionals in 2024: our selection

The table below recaps our selection of some of the best professional 3D printing options for office use. Our goal is to provide a quick, visual overview of the market; there are of course numerous other factors to take into account (material compatibility, certifications, customer service, software, etc.) before making the right choice.

| Brand | Product | Build size | Country | Price

Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …).

| |

|---|---|---|---|---|---|

| Prusa Research | Original Prusa i3 MK3S | 250 × 210 × 210 mm | Czech Republic | $ 999 | Quote |

| BCN3D Technologies

Product data validated by the manufacturer.

| Sigma D25 | 420 × 300 × 200 mm | Spain | $ 3,995 | Quote |

| INTAMSYS

Product data validated by the manufacturer.

| FUNMAT PRO 310 | 305 × 260 × 260 mm | China | $ 6,500 | Quote |

| Raise3D

Product data validated by the manufacturer.

| Pro3 Plus

This product has been reviewed by our team.

| 300 × 300 × 605 mm | United States | $ 7,599 | Quote |

| Ultimaker | Ultimaker S7 | 330 × 240 × 300 mm | Netherlands | $ 8,299 | Quote |

| Markforged

Product data validated by the manufacturer.

| Onyx Pro (Gen 2) | 320 × 132 × 154 mm | United States | $ 9,600 | Quote |

| Stratasys

Product data validated by the manufacturer.

| F120 | 254 × 254 × 254 mm | United States | upon request | Quote |

The products in the table are ranked by price (low to high).

| Brand | Product | Build size | Build volume | Extruder temp. | Country | Price

Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …).

| |

|---|---|---|---|---|---|---|---|

| Prusa Research | Original Prusa i3 MK3S | 250 × 210 × 210 mm | 11.03 L | – | Czech Republic | $ 999 | Get a quote |

| BCN3D Technologies

Product data validated by the manufacturer.

| Sigma D25 | 420 × 300 × 200 mm | 25.2 L | – | Spain | $ 3,995 | Get a quote |

| INTAMSYS

Product data validated by the manufacturer.

| FUNMAT PRO 310 | 305 × 260 × 260 mm | 20.62 L | 300°C | China | $ 6,500 | Get a quote |

| Raise3D

Product data validated by the manufacturer.

| Pro3 Plus

This product has been reviewed by our team.

| 300 × 300 × 605 mm | 54.45 L | – | United States | $ 7,599 | Get a quote |

| Ultimaker | Ultimaker S7 | 330 × 240 × 300 mm | 23.76 L | – | Netherlands | $ 8,299 | Get a quote |

| Markforged

Product data validated by the manufacturer.

| Onyx Pro (Gen 2) | 320 × 132 × 154 mm | 6.5 L | – | United States | $ 9,600 | Get a quote |

| Stratasys

Product data validated by the manufacturer.

| F120 | 254 × 254 × 254 mm | 16.39 L | – | United States | upon request | Get a quote |

Overview of the best professional 3D printers in 2024

In this section, we give some more context and information about each pro 3D printer from our selection.

Prusa Research Original Prusa i3 MK3S overview

The Original Prusa i3 MK3S is a 3D printer produced by Prusa Research, a manufacturer based in the Czech Republic.

It uses the Fused Filament Fabrication technology to produce thermoplastics parts using filament feedstock.

It offers a build volume of 250 × 210 × 210 mm.

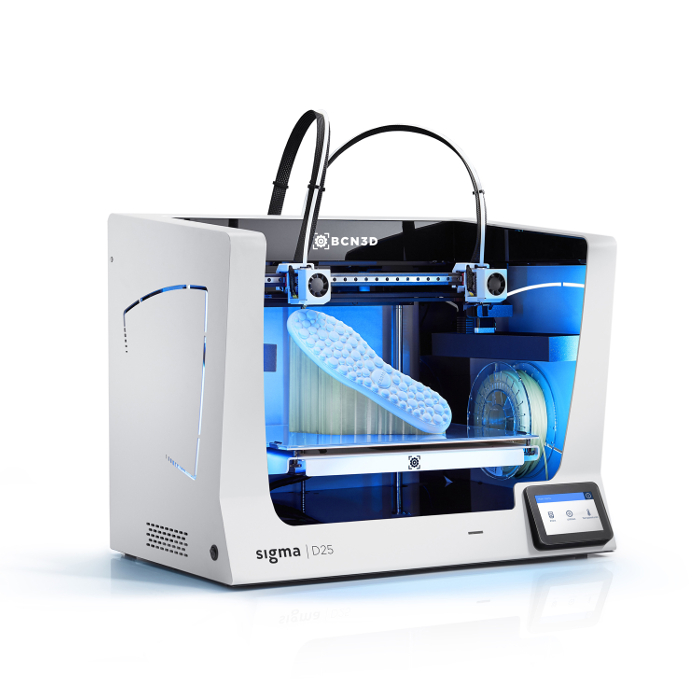

BCN3D Technologies Sigma D25 overview

The Sigma D25 is a 3D printer produced by BCN3D Technologies, a manufacturer based in Spain.

It uses the Fused Filament Fabrication technology to produce elastomers and thermoplastics parts using filament feedstock.

It offers a build volume of 420 × 300 × 200 mm.

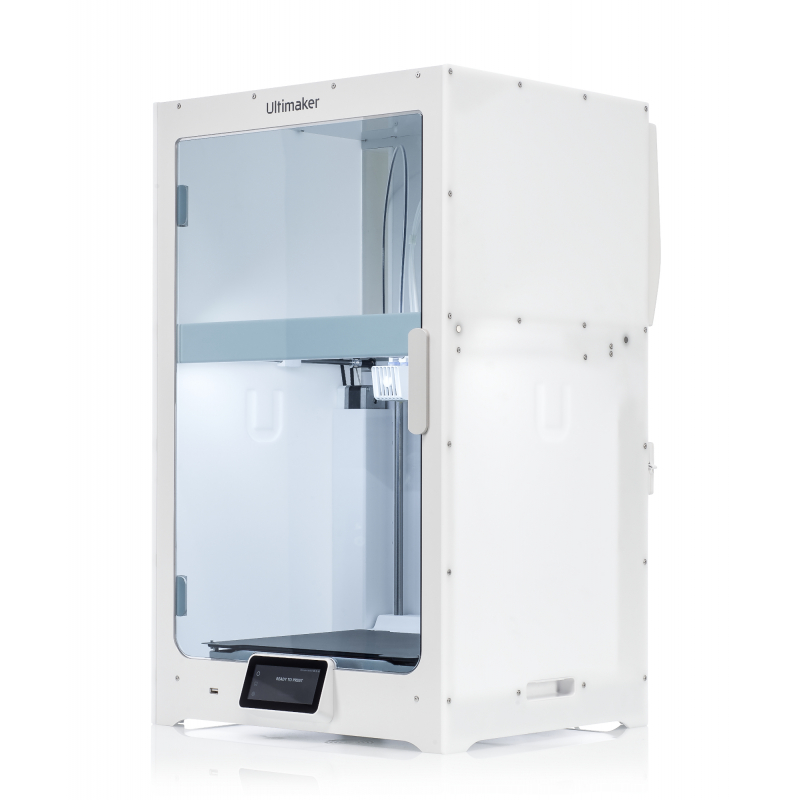

Ultimaker Ultimaker S7 overview

The Ultimaker S7 is a 3D printer produced by Ultimaker, a manufacturer based in the Netherlands.

It uses the Fused Filament Fabrication technology to produce thermoplastics parts using filament feedstock.

It offers a build volume of 330 × 240 × 300 mm.

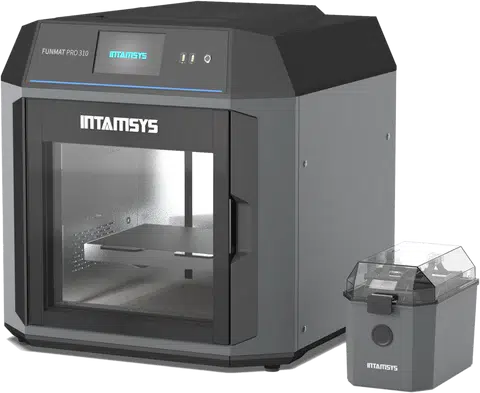

The FUNMAT PRO 310 is a professional industrial grade high-performance 3D printer produced by INTAMSYS. INTAMSYS is a 3D printer manufacturer based in China. The INTAMSYS FUNMAT PRO 310 uses extrusion 3D printing technology.

INTAMSYS specializes in high-temperature 3D printers for high-performance materials. These engineering materials include PEEK, PEKK, PC, and PEI (among others). With whole process control, the FUNMAT PRO 310 offers engineering material capabilities such as ASA, ABS, PC, PC-ABS, PA and PA-CF with INTAMSYS user-friendly 3D model-slicing software, INTAMSUITE. INTAMSYS 3D printers are all open material systems either welcoming INTAM™ filaments (which come with ready-to-print settings) or filaments from third-party manufacturers.

Bring industrial performance to your desktop/Industrial 3d printing performance accessible.

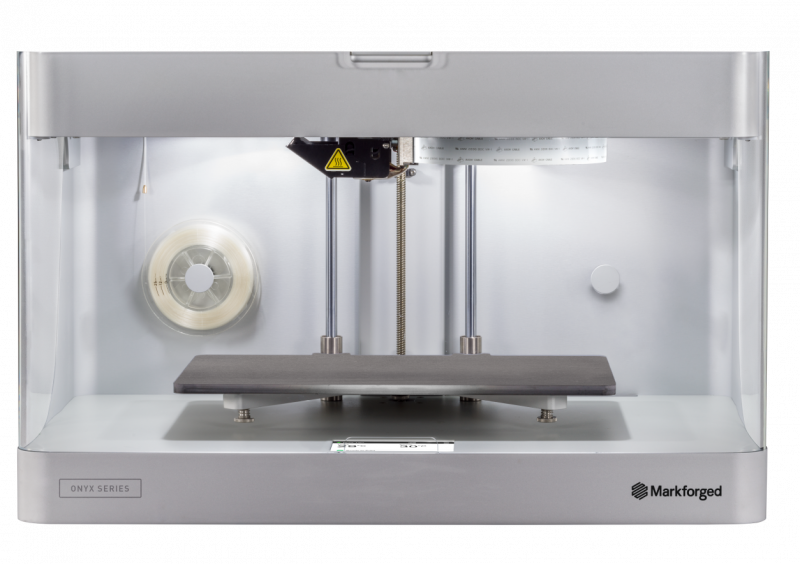

Markforged Onyx Pro (Gen 2) overview

The Onyx Pro (Gen 2) is a 3D printer produced by Markforged, a manufacturer based in the United States.

It uses the Continuous fiber deposition and Fused Filament Fabrication technologies to produce continuous fiber reinforced polymers, elastomers and thermoplastics parts using filament feedstock.

It offers a build volume of 320 × 132 × 154 mm.

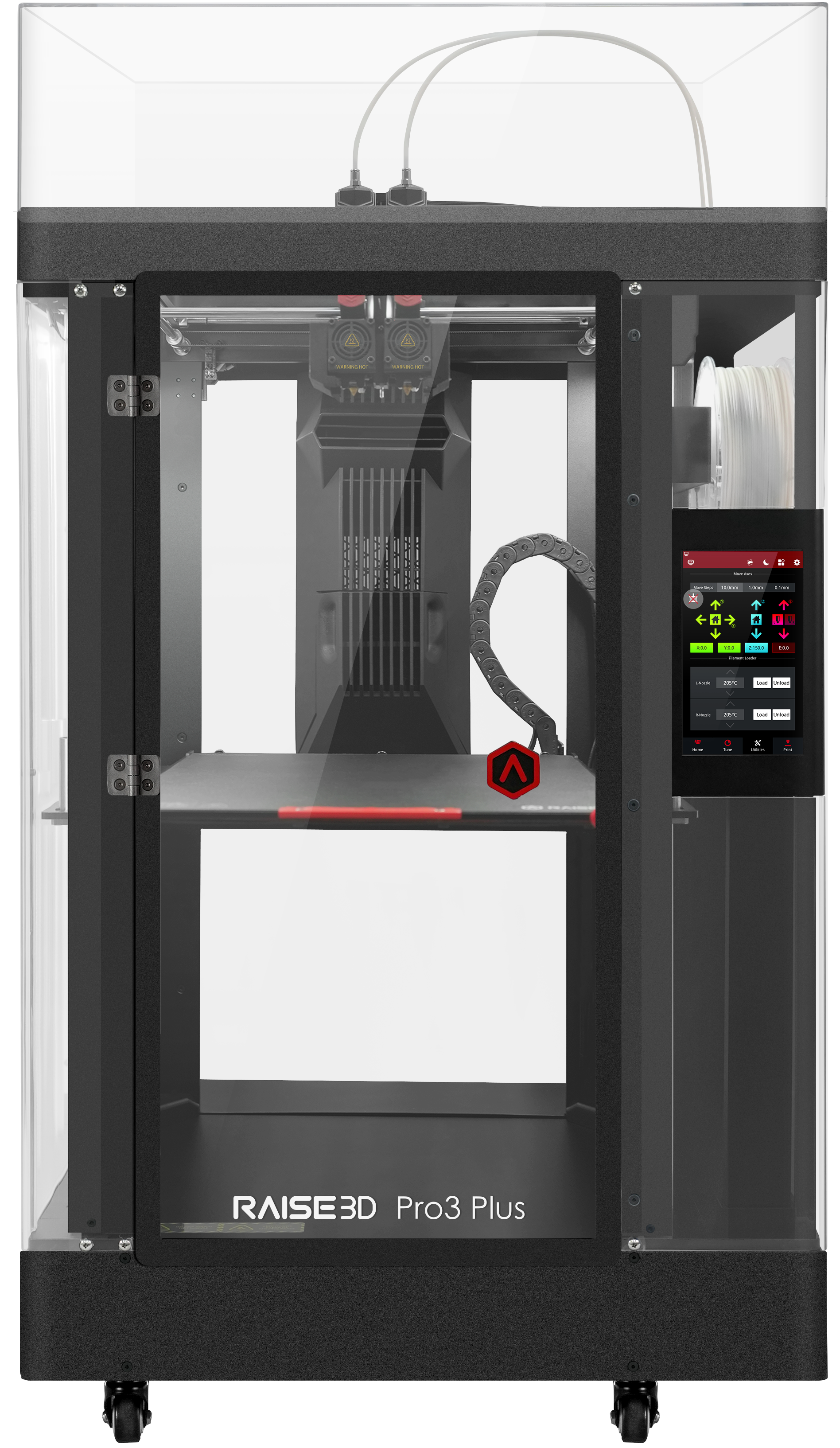

Raise3D Pro3 Plus overview

The Pro3 Plus is a 3D printer produced by Raise3D, a manufacturer based in the United States.

It uses the Fused Filament Fabrication technology to produce elastomers and thermoplastics parts using filament feedstock.

It offers a build volume of 300 × 300 × 605 mm11.81 × 11.81 × 23.82 in.

Stratasys is the Apple of the 3D printing industry. Their 3D printers, including the F120, are reliable machines with industrial-grade components and printing quality. However, Stratasys 3D printers generally only work with Stratasys materials and hardware. At the moment, less than a handful of filaments are available for the Stratasys F120.

The F120 is one of the most affordable FDM printers from Stratasys and is destined to be a desktop workhorse for professionals. Stratasys emphasizes on the printer’s ease of use, durability, and industrial quality.

Professional 3D printer buying guide

There are several features and specifications to take into account when choosing the best professional 3D printer for your needs.

Technology

For this professional desktop 3D printer selection, we focused on FFF (fused filament fabrication) 3D printers. They are ideal for creating both prototypes and end-use parts.

For professionals in dental or jewelry industries where high precision and detail are required, resin 3D printers are more adapted, with SLA, DLP, or LCD-based technologies.

There are also desktop SLS 3D printers (powder 3D printers), PEEK 3D printers, continuous fiber 3D printers, and more for advanced applications. Explore these topics with all of our other 3D printer guides.

Build plate or print bed

A heated print bed is mandatory for users that need to 3D print with ABS and other more demanding materials. The heat helps prevent warping and offers better first-layer adhesion.

While today’s 3D printers almost always feature heated build plates, they don’t all reach the same temperatures. It is best to know which thermoplastics you will be printing and to choose your desktop 3D printer accordingly.

Some professional 3D printers have interchangeable build trays to help speed up the workflow, enabling users to quickly launch new prints while the previous build plate cools down. On higher-end 3D printers, there can even be vacuum systems for instant part release from the print bed.

Print head

PLA and ABS can be considered the most common and basic 3D printing materials in general. Professionals, however, often need to print more complex materials, such as Nylon, Polycarbonate, PETG, ASA, or other engineering-grade polymers.

They don’t all have the same melting or glass transition temperature and therefore have to be 3D printed at different temperatures. For example, PLA can be extruded at around 200°C, PC at around 260°C, and some high-performance materials like PEEK or PEKK need the extruder to reach at least 450°C.

Popular professional filaments also include plastics filled with carbon fiber or glass fiber for increased strength and resistance. These materials are abrasive and require tough nozzles; many professional printers are already compatible with these composites, but it’s important to make sure beforehand.

Some 3D printers are compatible with multiple types of nozzles with varying diameters, and even paste-type print heads exist to 3D print clay.

Automatic calibration

Most professional 3D printer systems are equipped with automatic calibration features to make the process as plug-n-play as possible. It’s important to recalibrate a 3D printer from time to time to ensure consistent print quality.

There are two main types of calibration:

- Print bed leveling (making sure the print bed is perfectly parallel to the nozzle, and not tilted)

- Nozzle offset (determining the right gap between the nozzle and the print bed)

Most 3D printers for professionals feature a probe attached to the print head to automate these processes instead of users having to use a piece of paper or business card.

Some 3D printers also have NFC readers to automatically adjust their temperature settings according to the detected material (so long as the spool is chipped, too).

Dual extrusion and independent dual extrusion (IDEX)

A dual extruder enables users to 3D print with two different colors or materials simultaneously, including soluble support material for complex objects.

If there are two separate print heads, the system is referred to as IDEX (independent dual extruder). BCN3D Technologies was one of the first manufacturers to offer this feature a few years back.

In addition to being able to 3D print two materials at a time, independent dual extrusion offers different 3D printing possibilities:

- Duplication mode: 3D prints two identical objects at the same time.

- Mirror mode: to 3D print an object twice as fast as with just one extruder, each nozzle completes one-half of the object.

Onboard camera

Some 3D printers are equipped with an onboard camera that monitors prints remotely or saves time-lapse videos. This feature can be useful if the printer must be left unattended for long periods of time. We found it to be quite practical when we launched a long print for our Pro3 Plus review.

With the right 3D software, onboard cameras can help with quality control. Quality control can also be done during post-processing workflows with a metrology 3D scanner.

Minimum layer thickness

3D print quality is intricately linked to layer thickness, a.k.a. layer height or Z resolution. It’s the minimum height of each successive layer that forms the 3D printed object. The thinner the layers, the less they are distinguishable and the smoother the object will be (similar to the ratio of pixels in an image).

Thinner layers also mean that more layers are required to complete the object, which translates into more 3D print time. Layer thickness can be adjusted depending on if you need a quick print (thicker) or a high-resolution print (thinner).

The typical minimum layer thickness for mid-range FFF 3D printers is 100 microns or 0.1 millimeters, but it can go down to 0.01 mm in some cases.

Build volume

The build volume is the maximum size that your prints can be. If you need a bigger volume than what the 3D printers in this guide provide, you may be interested in these selections:

Now, there are even large-sized resin 3D printers for those that need both volume and finer surface quality.

Closed frame

Many variables can interfere with 3D print quality, such as temperature changes and room drafts. Hence, 3D printers with an enclosed build chamber tend to provide better quality prints, in addition to reducing noise, odors, and– with a HEPA filter– harmful particle emissions.

A closed frame is almost mandatory when 3D printing with basically anything other than PLA. Today it is quite rare to see a professional 3D printer without an enclosure.

FAQ

With basic precaution, 3D printers are relatively safe to use, although there has been some concern over harmful particle emissions from the melted filament. It’s best to use closed 3D printers with filters and to use 3D printers in well-ventilated areas. Users should also be careful not to burn themselves on a hot build plate or extruder; some 3D printers feature door safety sensors to lock the printer while it is printing.

Yes, some FFF 3D printers are able to print metal-filled filaments. This is called metal FFF. Once the part has been 3D printed, however, it must undergo two processes called debinding and sintering. Other types of 3D printers (much more expensive and industrial-grade) are able to 3D print metal powder using various metal 3D printing technologies like L-PBF (laser powder bed fusion) or metal binder jetting, among others.

For jewelry, resin 3D printers are more adapted than FFF 3D printers. They use SLA, DLP, or LCD-based technologies to produce objects with fine details and smooth surfaces.

Yes, some 3D printers can print in color. They are called full-color 3D printers and often use powder-based technologies. Systems that mix CMYK filaments exist, but cannot reproduce photorealistic colors like powder-based 3D printers.

English

English  Français

Français