3D printing for toys

What is the added value of 3D printing for the toy industry?

Since many toys are made of plastic, 3D printing has quickly proved to be an excellent solution to repair broken toys, replace missing toy parts or 3D print your own toys at home. You can just download the 3D model you need and 3D print it.

Free STL file platforms such as Thingiverse or Shapeways have sections dedicated to toy making. If you do not find what you were looking for or want an original model, you might need to design it, using 3D software or via a 3D printing service.

3D printing toys at home

Creating 3D printed toys

With 3D printing, it is now possible to create your own unique toys at home. For instance, designers from MyMiniFactory have designed and 3D printed a life-size World of Warcraft sword!

Besides, with the fast growth of 3D pens (check this 3D pen tutorial out!), it becomes possible to create your own 3D printed toys by drawing them directly in 3D. It only takes a few minutes to create a small object.

Improving and customizing toys with 3D printing

3D printing allows you to modify or improve some of your favorites toys, mostly figurines. On Shapeways, you can buy (or download their 3D models) helmets, headgear, and weapons for LEGO or Playmobil to enhance these figurines.

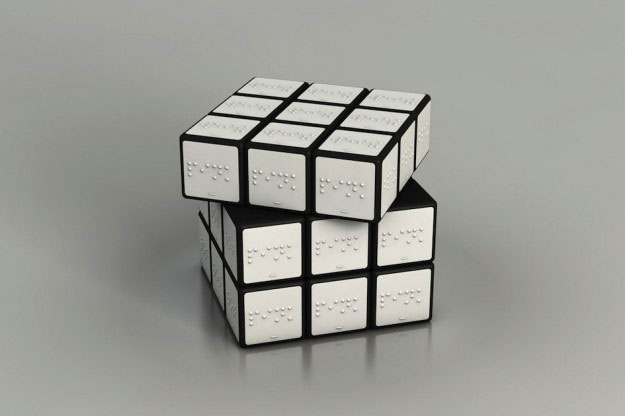

Another example of how 3D printing can improve toys: the classic Rubik’s cube is now available in braille version for the visually impaired.

3D printing: bringing new business opportunities for manufacturers

Prototyping and testing toys with 3D printing

Toy manufacturers increasingly leverage 3D printing in their production processes. By 3D printing toy prototypes, manufacturers can control the quality of the design and compare different versions while verifying that the toy parts fit well together. This verification enables them to identify potential issues at an early stage and at a relatively low cost, thus leading to substantial gains in productivity.

Offering a better customer experience

3D printing can also be used to improve the consumer experience. McDonald’s for example announced several years back that they were considering the idea of 3D printing Happy Meal toys directly in its restaurants. The idea was that children could simply choose their toys on-screen and customize and print them in 3D. It is an opportunity to improve the customer experience in the restaurant during the preparation of the meals.

Much ink has flowed since this interview of Mark Fabes, IT Director of McDonald’s UK, but nothing has been launched yet. Indeed, Mark Fabes said that “this was only an idea”. Still, this ‘idea’ reveals the potential that brands see in 3D printing to improve their customers’ experience.

Engaging with fans and customers

For toymakers, 3D printing is also an opportunity to interact with their customers. With 3D printing, they have the opportunity to involve the fans in the design process and therefore to create a much closer relationship between customers and the brand.

Plus, the customer experience is enhanced by the ability to create or customize their own toys. That’s why leading toy manufacturers such as Hasbro (Monopoly, Disney, Pokemon) will soon offer customers the possibility to customize some of their best-selling items using 3D printing and the section Superfanart on Shapeways.

Logistical improvements and productivity gains with 3D printing

In the long run, leveraging 3D printing could lead to significant gains for toy manufacturers. Indeed, they could go from selling actual toys to selling only 3D files of toys. They would then transfer the manufacturing part to the customers, avoiding all the packaging and shipping.

Another way of making productivity gains would be allowing the customers to customize toys using 3D printing. Toy manufacturer Mattel and 3D software giant Autodesk will soon enable 3D printed customizations by their users. It will be similar to shoe customization service NikeiD. All of these future customer-friendly apps should allow customers to make or add specific elements from a predefined list to a generic toy.

3D printing toys for kids and for babies

Great educational toys

Tinkerplay is a software made for children by Autodesk. Using predesigned modules, children can draw characters in a few clicks by choosing faces, arms, colors, and textures. The 3D model can then be printed using a 3D printer.

3D pens also allow to draw and create a 3D object in seconds. They can be great as toys to foster kids’ creativity. 3D printing pens can help children develop their design skills and understanding of space (dimensions).

3D printed objects intellectual property

Intellectual property for 3D printed objects

One of the major issues at stake with 3D printing is how to protect the intellectual properties of toy manufacturers while introducing 3D printing in their business models.

Indeed, the challenges faced by many manufacturers with 3D printing – not only in the toy industry – are similar to the threats posed to the music industry when digital formats such as mp3 emerged. Piracy and illegal downloads of 3D files could jeopardize many traditional manufacturers.

We can definitely imagine that, in a near future, everyone could become capable of 3D printing toys such as LEGO or Playmobil for free by using illegally downloaded 3D files of these objects.

For now, many toy manufacturers do not feel concerned because of the complexity of their parts, forcing fans to buy licensed products. But this situation could change sooner than they expected.

Actually, it already happened to the famous board-game company Games Workshop, founder of the Warhammer series. Many fans have already designed unofficial 3D models of Warhammer figurines and shared the 3D files on 3D printing communities, thus triggering legal action from Games Workshop.

It is clear that, in order to take full advantage of 3D printing, new business models will emerge, designed by toy manufacturers, but also by users or contractors, seeing in 3D printing a turning point, an opportunity. Maybe one day, toys won’t be in stores anymore. Instead, we will buy the right to 3D print a toy at home or in a 3D printing service via an official and secured 3D file. Maybe. Intellectual property is one of the key points of these business models… To be continued!

Case study: Codename Colossus

A 435 3D printed parts tank

Singapore artist Michael Sng has designed and manufactured his dream toy: an animated tank with cannons and rifles, made out of 435 3D printed and hand-painted pieces.

Inspired by an imaginary world war, this tank is a unique piece that the creator still hesitates to put on the market. “More accessible versions are not the same size and could probably not be completely 3D printed or assembled by hand!“. When we see the enormous task that this represents, we understand why!

English

English  Français

Français