3D scanning and 3D printing for jewelry

Jewelry, an ancient craft, is increasingly turning to the modern technology of 3D printing to improve design and production processes. The top applications of 3D printing for jewelry are in prototyping and direct manufacturing of jewelry.

- Prototyping: Professionals in the jewelry sector can save time and money by using 3D printing. Indeed, jewelers can make cost-effective plastic prototypes of jewelry pieces before sending the final design to production.

- Making patterns for casting: 3D printing can also be used in the manufacturing process of jewels to make patterns for investment casting.

- Direct manufacturing: It is possible to 3D print actual jewelry by using metal 3D printers. As metal 3D printing is still an expensive technology, users often send their 3D designs to 3D printing services such as Shapeways or Sculpteo. These services offer a wide range of 3D printing materials, including precious metals such as silver, gold, or platinum.

The main technologies used for prototyping and investment casting in jewelry are resin-based, such as laser SLA or DLP. These resin photopolymerization 3D printing technologies allow to 3D print objects with a smooth surface and a high level of details– two requirements for jewelry 3D printing.

3D printing custom jewelry at home

Many 3D design directories list 3D jewelry designs that are ready to print on a desktop 3D printer. Of course, there are limits depending on the type of material a 3D printer can use, either plastic-based filament for FFF 3D printers or photopolymers for resin 3D printers.

However, with exotic 3D filaments, it is now possible to print metallic-looking objects with a regular desktop 3D printer.

What are the benefits of 3D printing for jewelry?

- Cost-effective: It can be cheaper to produce a prototype via 3D printing rather than with a traditional fabrication technique or tool, such as CNC milling.

- Fast: Using a rapid prototyping or manufacturing process such as 3D printing can significantly shorten the product design and production cycle.

- No limitations on 3D designs: 3D printing allows designers to use complex shapes and intricate designs which would be impossible to fabricate with traditional manufacturing techniques. This aspect is important in a creative field such as jewelry.

3D printing jewelry for professionals

3D printing for casting metal jewels

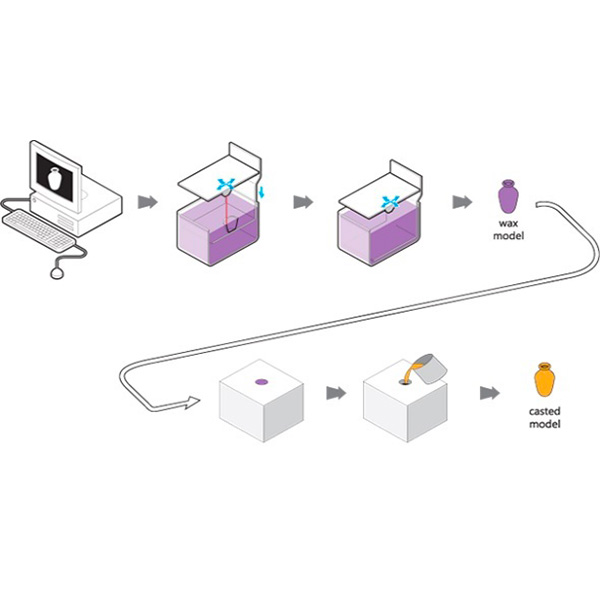

A very efficient technique to make jewelry relies on the fabrication of molds. Lost wax casting is a popular technique for directly producing metal jewels from 3D printed models.

In this case, a 3D printed model of the piece of jewelry is first made of thermoplastic wax. Then, a mold (also called investment) is created around the 3D printed jewel. The investment is heated until the thermoplastic wax melts away.

From there, liquid metal (e.g. gold, platinum, or silver) is then poured into this digitally-designed mold. Once the metal has cooled, the jeweler can add gemstones.

Many SLA 3D printer manufacturers develop specially formulated resins for jewelers and their use cases.

Metal 3D printing for jewelry

3D printing makes it possible to manufacture small, complex metal parts of high quality and at speed.

One popular technology for 3D printing jewelry is Direct Metal Printing (DMP). Compatible materials are standard metal alloys and ceramics.

In this case, it is also possible to work directly with precious metals and make custom jewels on-demand, without any stock. The parts do, however, usually require some post-processing for a perfect look.

The best 3D printers for jewelry

3D printing technologies for jewelry: laser SLA, DLP, and LCD

Most often, the 3D printing technologies used in jewelry applications are resin-based 3D printing technologies: mainly laser SLA (stereolithography), DLP (Digital Light Processing), or LCD/MSLA (masked stereolithography). The best 3D printers for jewelry use these methods because resin 3D printing can produce higher quality prints and smoother print surfaces than extrusion-based (FFF) 3D printers, which use plastic filament as a consumable.

3D printing resolution is critical in jewelry applications because the final products, jewels, are often tiny objects with high levels of detail. Smooth surfaces are also required when using 3D printing to create molds for investment casting, for example.

Jewelry 3D printer prices

There are several 3D printer brands specializing in jewelry applications. Prices start from a few hundred dollars for entry-level desktop 3D printers using resin technologies.

For more advanced resin 3D printers specifically designed for jewelry applications, prices can go much higher based on a variety of criteria, from print resolution to build volume, print speed, and more.

3D scanning for jewelry

3D scanning for jewelry delivers many advantages. This process allows you to get a detailed CAD file of a piece of jewelry, and capture a high level of details.

Benefits of 3D scanning for jewelry

3D scanning brings a lot of improvements to the existing jewelry-making process. It is a fast, very accurate, and cost-effective method to capture pieces of jewelry.

Here are some examples of applications and benefits of 3D scanning for the jewelry market:

- 3D scanning a piece of jewelry to obtain a detailed CAD file of the piece. This 3D file is much more accurate than a picture, as every single detail and shape will be captured by the 3D scanner. Storing such digital files for later use (showcasing, archiving, modifying designs, etc.) is then easy.

- Creating a new design based on an existing jewelry piece. You just need to 3D scan the original model and edit it in with CAD software. You can then 3D print the model to build a mold for your new designs for example.

- Capturing a high level of details to detect imperfections. 3D scanning a jewel or gem allows you to easily identify any defaults or design flaws.

- Repairing a broken or damaged jewel. Thanks to the high accuracy offered by jewelry 3D scanners, you’ll be able to design a perfect fix for the damaged piece of jewelry. In such cases, it can be all the more interesting to use 3D printing, in order to 3D print a custom mold for the piece.

- Replicating existing pieces of jewelry. 3D scanning might be useful if you need an accurate copy of an expensive piece or if you want to reproduce an existing jewel.

The best 3D scanners for jewelry

3D scanning can bring several advantages to the design and production processes in jewelry, but capturing pieces of jewelry in 3D can be challenging.

Indeed, 3D scanning small objects with a high level of details requires specific 3D scanners with a high resolution.

Besides, 3D scanning transparent or translucent objects is a difficult task that can be achieved by using a specific coating powder or spray to enable the 3D scanner to “see” the object.

These desktop 3D scanners can be enclosed or open and they are usually based on structured light technology.

Several 3D scanner manufacturers have developed 3D scanners to specifically address the needs of jewelry professionals. Visit our 3D jewelry scanners buyer’s guide for more information.

How to make 3D printed and customized jewelry at home?

Where to download 3D printing jewelry files?

Many online platforms offer a wide choice of 3D files for jewelry. Thingiverse and Cults3D have hundreds of different designs, downloadable for free or at a small cost.

In many cases you can even contact the designers and request specific customizations.

Before printing the 3D file of the jewel, the most important things to check are the scale of the model and its orientation on the printing bed.

3D printing jewels with a 3D desktop printer

Most common personal 3D printers use the Fused Filament Fabrication (FFF) to create objects in plastic. They offer lots of colors and are great for 3D printing costumes and fashion jewelry. 3D printed rings, bracelets and pendants are easy to design and simple to 3D print at home.

With several options of shape and size, 3D printed plastic jewelry and fashion accessories are some of the most accessible objects produced by 3D printers.

English

English  Français

Français